Keith from WaterAid and me at Coppermills Treatments Works Thames Water site, Dec 2017.

In this rather geeky post, I’m sharing what I’ve learned during a research visit at Coppermills Water Treatment Works, Thames Water site, filtering around 30% of London’s drinking water. This secure site has its gates firmly shut to most passers-by (I’ve tried to get in to see what’s going on there before). I feel very special to have been able to go there this time! I need to say a big thank you to Deena from Thames Water and Keith from WaterAid to grant me access to the site, on which they both accompanied me in December 2017.

There are several stages of water filtration, here I share some knowledge learned during our research trip at the Coppermills Water Treatment Works.

Rapid gravity filters trigger the cycle of the filtering. The whole process lasts 12 hours from start to finish, and then it continues to water service reservoirs. Rapid gravity filters are large open top tanks of passing water. Any big particles such as grass, feathers and other bits that haven’t been stopped by grids on their way from Thames Water reservoirs to Coppermills are removed. This process takes 15 minutes, hence its name, rapid. The rapid gravity filters are maintained by reverse flashing the water flow upwards and the large particles are directed and diverted out of the filter where they are caught and removed.

Rapid Gravity Filters at Coppermills.

Ozone gas is added at the second stage of filtering and it is injected into the water to remove pesticides and organic material. The process of ozonization has antibacterial properties and the water leaves in two separate streams and is directed to, for me the most interesting stage of water filtration, Slow Sand Filtration.

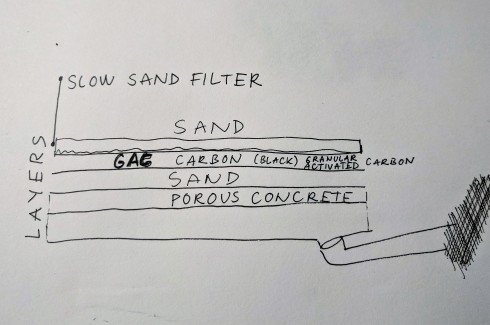

Slow Sand Filtration works on large-scale filter beds. There are over 33 slow sand filter beds at the Coppermills site. It was fascinating to watch how the workers immaculately layered the sand in one of the filter beds and sitting in a large vehicle leveled the elements. The birds try to help too, leaving their mark.

Sketch of a slow sand filter, S Krupinska 2018.

After the water passes through very fine, around 400-micron stainless steel mesh screens (2×3 m large), it heads for about 3 hours to the final disinfection area. My words couldn’t describe this process better than the explanation on Thames Water website: “Chlorine is dosed at the end of treatment before the water is sent into supply to destroy harmful micro-organisms. The disinfection process is performed in specially designed contact tanks, which contain a series of baffles. The tanks ensure that the chlorine remains in good contact with the water for a set amount of time, to ensure effective disinfection before it is sent into the distribution network.”

The water after this stage is sent to service reservoirs, each area has their own enclosed water storage facility. I’ve investigated where is my nearest Service Pumping Station. I found it in Streatham. The following link takes you to it.

Why am I researching this topic and what am I working on? Learn about my big project coming up in a museum in May 2018 here.

Thank you very much for reading this blog post. See you soon.

2 comments

Comments feed for this article

February 15, 2018 at 7:37 pm

WaterAid Project for Dambusters Week at RAF Museum | Silvia Krupinska - Organic Contemporary Sculpture Blog

[…] With a winter frost and wind, an art commission has landed on my art studio doorstep. I’ve been interested in the water filtration processes since my Walthamstow Wetlands Art residency (2015-2016) and my dream project based on these dynamic systems is now happening! Wateraid‘s Learning Department approached me at the end of 2017, however, I’ve kept it quiet as things have been developing. Now, after a couple of research visits at Thames Water’s Coppermills Water Treatments Works and at the Royal Air Force museum where the installation will feature during a week-long of events celebrating the 75th anniversary of Dambusters in May 2018, I’m firmly engaged in the process and very excited. To read a blog post about water filtering research visit at Coppermills click here. […]

July 22, 2019 at 5:08 pm

Abstract Return 14 Billion | Silvia Krupinska - Organic Contemporary Sculpture Blog

[…] Thank you for stopping by. If you would like to read more and see some more images on my website. Click this link. To learn more about water filtration and my research trip to a Thames Water water plant click here. […]